Understanding Anti-Glare Glass: Key Features & Applications

Anti-Glare Glass (AG Glass) addresses the issue of distracting reflections. It subtly textures its surface, converting harsh specular glare into softer, diffused light. This substantially enhances visual clarity in bright environments, such as sunlight or intense indoor lighting, while preserving the glass's fundamental optical properties. Let's delve into its specifications, manufacturing process, and areas of excellence.

1. Standard Specifications

AG Glass parameters vary based on application needs. Key metrics include:

| Parameter | Typical Range | Measurement Method | Importance |

| Light Transmittance | 88–91% (float glass), up to 93% for chemically etched Gorilla Glass 610 | Spectrophotometer (380–700 nm wavelength) | Critical for maintaining image brightness and color accuracy. |

| Haze | 1–40% | Haze meter (ASTM D1003) | Higher haze reduces glare but may slightly lower image sharpness. |

| Gloss | 8–130 GU (Gloss Units) | Glossmeter (ASTM D523) | Lower gloss values (e.g., 8–20 GU) provide stronger anti-glare effects. |

| Thickness | 0.1–10 mm | Micrometer or caliper | Determines mechanical strength and suitability for thin devices. |

| Surface Roughness | 0.05–3.5 μm (Ra) | Profilometer (ISO 4287) | Influences light diffusion and tactile feel. |

| Particle Span | 1–5 μm | SEM imaging or optical microscopy | Ensures uniform light scattering for consistent anti-glare performance. |

2. Manufacturing Methods

AG Glass is produced through three primary techniques:

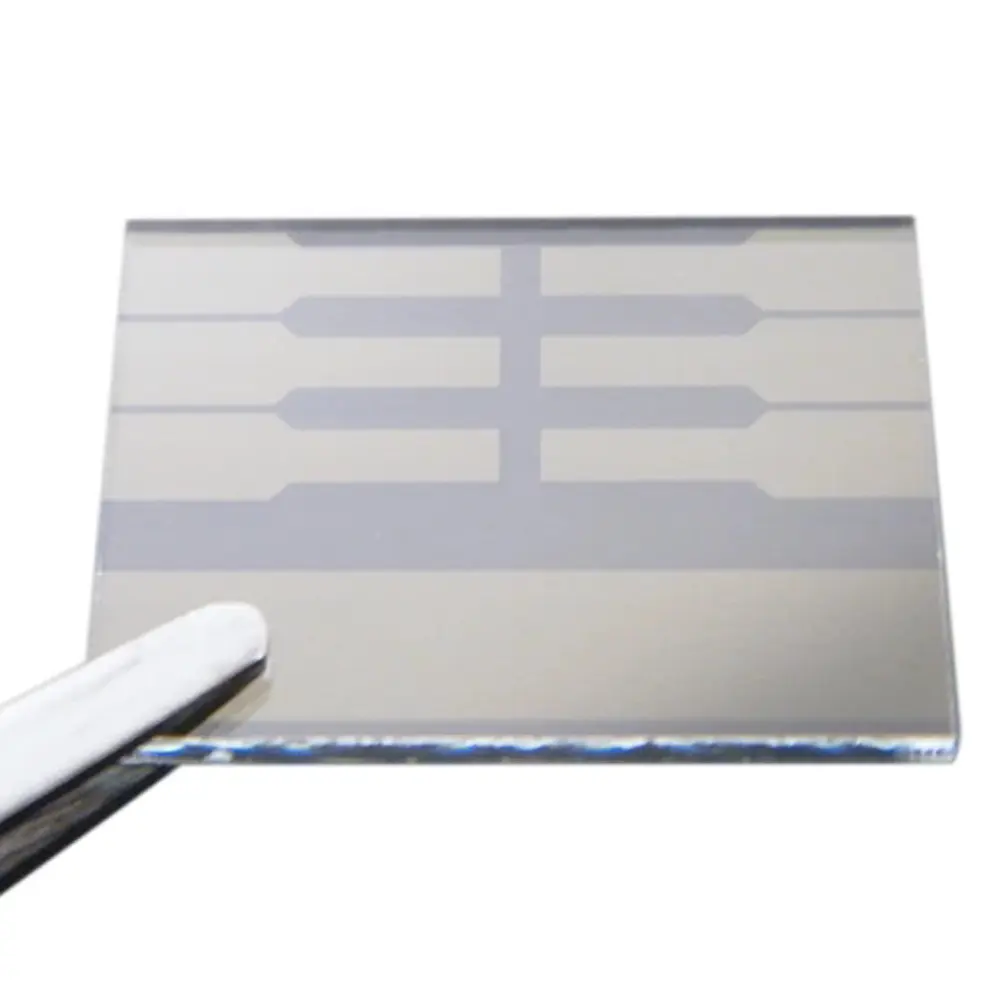

a. Chemical Etching

- Process: Glass is submerged in acidic solutions (e.g., hydrofluoric acid) to etch microstructures (1–5 μm) into the surface, converting specular reflection to diffuse reflection.

-

Advantages:

- Durable and scratch-resistant (surface remains glass).

- Compatible with subsequent treatments (tempering, coating).

- Uniform particle distribution for consistent optical performance.

- Applications: High-end displays, automotive dashboards, and outdoor signage.

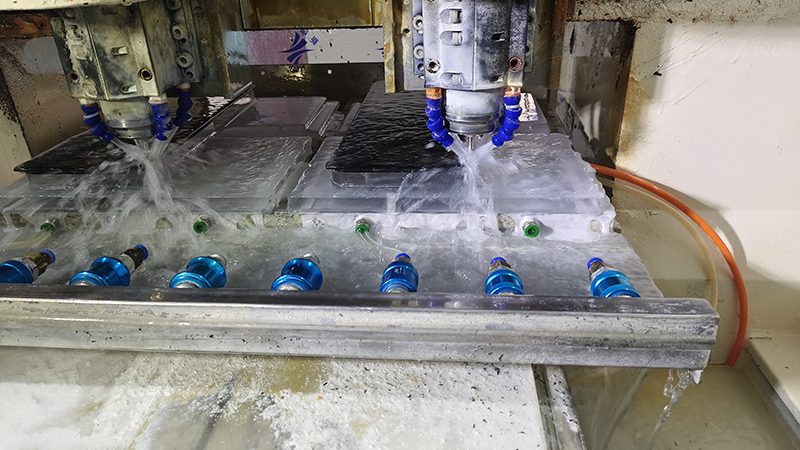

b. Physical Spraying

- Process: Submicron silica particles are sprayed onto the glass surface, forming a matte layer through thermal curing .

- Advantages:

- Cost-effective for large-scale production.

- Adjustable haze/gloss levels for customization.

-

Limitations: - Coating may delaminate in harsh environments.

- Less suitable for high-touch applications.

c. Coating Techniques

- Process: Anti-glare films or sol-gel coatings are applied to the glass surface to create a diffusive layer .

-

Advantages:

- High transmittance (up to 93%) with low haze.

- Ideal for curved or complex geometries.

-

Limitations: - Thinner coatings may wear over time. Hardly apply this technology currently.

3. Applications and Technical Requirements

AG Glass is widely used across industries, with specific technical demands for each scenario:

a. Consumer Electronics

-

Devices: Laptops, tablets, smartphones, and touchscreens. -

Technical Requirements:

- High Transmittance: ≥90% to preserve display brightness 6.

- Low Haze: <5% to maintain image sharpness.

- Surface Hardness: 7H or higher to resist scratches 10.

- AG Method: Chemical etching preferred for durability in high-touch environments.

b. Automotive

-

Applications: Dashboard displays, rearview Mirrors, and head-up displays (HUDs). -

Technical Requirements:

- Low Reflectivity: <1% to reduce driver distraction 6.

- Thermal Stability: Resistant to extreme temperatures (-40°C to 85°C).

- Impact Resistance: Tempered AG glass for safety 13.

- AG Method: Chemical etching for outdoor visibility.

c. Industrial and Medical

-

Applications: Control panels, medical equipment, and cleanroom displays. -

Technical Requirements:

- Anti-Microbial Coating: Optional for medical environments.

- Chemical Resistance: Resistant to disinfectants and solvents.

- Uniform Diffusion: Consistent haze (10–20%) for readability in harsh lighting 18.

- AG Method: Chemical etching for long-term reliability.

d. Architectural and Art Display

-

Applications: Museum exhibits, high-end windows, and art frames. -

Technical Requirements:

- Ultra-Low Reflectivity: <0.5% to eliminate glare on artwork.

- UV Protection: Coatings to prevent color fading.

- Aesthetic Matte Finish: Gloss <10 GU for a non-reflective appearance.

- AG Method: Chemical etching or specialized coatings for optical purity.

| Industry | Key Requirement | AG Method | Typical Transmittance | Gloss (GU) | Haze (%) |

| Consumer Electronics | High clarity | Chemical Etching | 88–93% | 20–50 | 2–5 |

| Automotive | Low reflection | Chemical Etching | 85–90% | 10–20 | 5–10 |

| Industrial | Durability | Chemical Etching | 88–91% | 30–80 | 10–20 |

| Architectural | Aesthetic matte finish | Coating/Spraying | 85–90% | <10 | 15–30 |

For more details learning and discussion, welcome to contact us : sales@saidavn.com

Phone

Phone Send Email

Send Email whatsapp

whatsapp Facebook

Facebook