In the rapidly evolving glass manufacturing industry, the demand for enhanced durability has never been more critical. According to a recent report by Market Research Future, the global coated glass market is projected to reach USD 10.32 billion by 2025, growing at a CAGR of 8.4% from 2018 to 2025. This growth is driven by the increasing need for energy-efficient and durable materials across various sectors, including construction and automotive.

Coated glass has emerged as a leading solution, providing superior resistance to environmental stressors while maintaining aesthetic and functional qualities. As industries seek innovative methods to improve product longevity, it's essential to explore the various technologies and applications associated with coated glass. This checklist aims to guide stakeholders through the key considerations and innovations that enhance the durability of coated glass products.

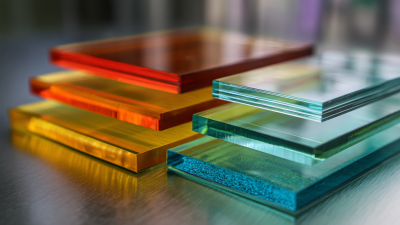

Coated glass products have gained significant traction in various industries due to their impressive durability and performance capabilities. There are primarily two types of coatings used on glass: low-emissivity (low-E) coatings and reflective coatings. Low-E coatings serve to minimize the amount of ultraviolet and infrared light that can pass through the glass without compromising the amount of visible light. Research by the Lawrence Berkeley National Laboratory indicates that using low-E coated windows can reduce household energy usage by up to 30%, highlighting their effectiveness in enhancing energy efficiency and durability.

Reflective coatings, on the other hand, are designed to improve the glass's ability to reflect solar energy while enhancing privacy and glare control. According to a report by MarketsandMarkets, the global market for coated glass is projected to reach approximately $78.1 billion by 2025, driven by the rising demand across the construction and automotive sectors. With enhanced durability, coated glass products not only extend the lifespan of structures and vehicles but also contribute to sustainable design practices, making them a vital choice for modern architectural applications.

| Type of Coated Glass | Durability Benefits | Applications | Maintenance Requirements |

|---|---|---|---|

| Low-E Glass | Improved energy efficiency and UV resistance | Residential and commercial buildings | Low maintenance, regular cleaning |

| Tempered Glass | High impact and thermal resistance | Shower doors, glass facades | Requires careful installation |

| Insulated Glass Units (IGUs) | Enhanced insulation and condensation resistance | Windows, skylights | Moderate maintenance, seal checks |

| Fritted Glass | Increased durability and scratch resistance | Curtain walls, partitions | Minimal maintenance, occasional cleaning |

| Self-Cleaning Glass | Reduction in dirt buildup, UV protection | Windows, skylights | Low maintenance, self-cleaning properties |

The choice between coated and uncoated glass products can significantly impact the performance and durability of architectural and automotive applications. According to a report by Grand View Research, the global glass coating market is expected to reach USD 8.75 billion by 2025, reflecting an increasing preference for coated glass due to its ability to resist corrosion, UV damage, and scratching.

Coated glass products are designed to enhance durability, with hydrophobic and oleophobic properties that repel water and oil, which prevent the accumulation of dirt and grime. This not only extends the lifespan of the glass but also reduces the need for frequent cleaning, leading to lower maintenance costs.

Coated glass products are designed to enhance durability, with hydrophobic and oleophobic properties that repel water and oil, which prevent the accumulation of dirt and grime. This not only extends the lifespan of the glass but also reduces the need for frequent cleaning, leading to lower maintenance costs.

Furthermore, the durability of coated glass can be quantified in its performance metrics. A study published in the Journal of Architectural Engineering highlights that coated glass can offer up to a 25% increase in tensile strength compared to uncoated counterparts. This significant enhancement is crucial in environments subject to extreme weather conditions. Additionally, the energy-efficient characteristics of coated glass contribute to lower heating and cooling costs, promoting sustainability while maintaining structural integrity. As such, the comparative analysis between coated and uncoated glass highlights the pivotal role that innovative coatings play in enhancing product longevity and performance in various applications.

When evaluating the durability of coated glass products, performance metrics are essential in determining their long-term reliability and functionality. Coated glass often undergoes various exposure conditions, including weathering, thermal cycling, and mechanical stress. Testing these materials under real-world scenarios can provide invaluable insights into their performance. Key metrics include scratch resistance, impact resistance, and corrosion resistance, all of which contribute to the product's life expectancy and maintenance requirements.

Tips: When selecting coated glass for specific applications, consider the environmental factors it will be exposed to. High humidity and temperature fluctuations can significantly influence the durability of coatings. Additionally, always check the manufacturer's specifications regarding maintenance; some coatings may require special care to retain their properties over time.

Another vital aspect to consider is the testing standards used to evaluate coated glass durability. Industry-standard tests, such as ASTM and ISO protocols, help ensure that the coated glass meets safety and durability benchmarks. Understanding these standards can guide you in choosing higher-quality products that promise enhanced performance and longevity.

Tips: Engage with industry professionals to better understand the latest innovations in coated glass technologies. This can help you stay ahead of the curve and make informed decisions about product choices that align with your durability needs.

Innovative coating technologies have emerged as a cornerstone of modern industrial innovation, offering unparalleled capabilities to enhance the durability and functionality of various products, including coated glass. A recent review highlights the advancements in active anticorrosion and self-healing coatings, showcasing the potential of multi-action smart coating strategies. These coatings not only protect metal surfaces from corrosion but also possess self-healing properties, significantly extending the lifespan of coated products. Industry reports suggest that the market for such smart coatings is expected to grow at a CAGR of over 12% by 2025, driven by increasing demand for sustainable and durable materials.

Moreover, translucent photoluminescent coatings are gaining traction in smart window applications, presenting a dual benefit of visual comfort and energy efficiency. Research indicates that these innovative coatings can improve indoor lighting quality and reduce energy consumption in buildings, providing an eco-friendly alternative to traditional solutions. As industries continue to grapple with rising environmental concerns, the development and implementation of innovative coating technologies will be essential in driving sustainability and enhancing product longevity across various sectors. The integration of these advanced coatings into manufacturing processes reflects a broader trend toward adopting high-performance materials that address both efficiency and environmental impact.

The shift towards coated glass products is driven by the need for enhanced durability without compromising aesthetic appeal. Unlike traditional materials, coated glass offers superior resistance to scratches, chemicals, and UV rays. This longevity means less frequent replacements, significantly reducing long-term costs for both residential and commercial applications. As architects and builders recognize the tangible benefits of coated glass, including lower maintenance expenses and improved energy efficiency, the trend is gaining momentum in modern design.

Traditional materials often require more regular upkeep and eventual replacement due to wear and tear. In contrast, coated glass not only enhances the lifespan of structures but also contributes to energy savings through better insulation. By minimizing the need for repairs and renovations, coated glass emerges as a cost-effective solution over time. Property owners who invest in this innovative material find themselves benefiting from reduced overall expenditures and a more sustainable approach to building and design.