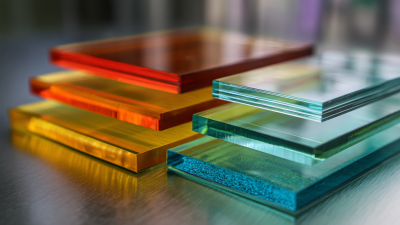

The integration of Cover Glass for Industrial PCs has become increasingly vital in enhancing system durability and performance across various sectors. As industrial environments present unique challenges such as exposure to dust, humidity, and physical impacts, utilizing robust protective solutions is imperative. Reports indicate that the global market for industrial PCs is projected to reach USD 4.3 billion by 2026, driven by the growing demand for reliable and resilient computing solutions. The adoption of cover glass not only improves resistance to scratches and chemicals but also enhances the overall aesthetic appeal of industrial systems. Additionally, studies show that implementing cover glass can increase the lifespan of industrial PCs by up to 30%, thereby reducing long-term maintenance and replacement costs. This paper delves into the multifaceted benefits of using Cover Glass for Industrial PCs, highlighting its critical role in safeguarding technology while optimizing operational efficiency.

Cover glass serves as a crucial enhancement for industrial PCs, providing robust protection that is essential in challenging environments. With industrial PCs often exposed to dust, moisture, and mechanical shocks, incorporating cover glass can significantly improve their durability. According to industry studies, devices equipped with cover glass can withstand impacts that exceed common thresholds, thereby extending their operational lifespan. For instance, a report highlighted that devices with enhanced protective features experience up to a 40% reduction in failure rates due to environmental factors, proving the value of investing in additional protective measures.

Moreover, cover glass not only enhances physical protection but also contributes to the overall performance of industrial PCs. When discussing operational efficiency, the use of cover glass has been linked to improved touch sensitivity and screen clarity, crucial for applications requiring precise interactions. The integration of cover glass can reduce glare and increase visibility, which is particularly important in manufacturing settings where screen readability can affect productivity. Industry data suggests that improved display characteristics can lead to a 20% increase in user efficiency, further supporting the case for its widespread adoption in enhancing industrial PC applications.

The integration of cover glass into industrial PCs has demonstrated significant impact on both performance and efficiency. Cover glass serves as a protective barrier against environmental hazards such as dust, moisture, and mechanical shocks, ultimately enhancing the longevity of these devices. By safeguarding sensitive components, the cover glass contributes to consistent performance, reducing the likelihood of hardware failures and downtime in industrial settings. Additionally, the optical clarity of high-quality cover glass ensures that display visibility remains uncompromised, facilitating better operator interaction with the equipment.

Tips for selecting the right cover glass include considering factors such as the thickness, hardness, and anti-reflective coatings. Thicker glass can offer greater protection but may add weight, which is crucial for mobility-oriented applications. Opting for tempered or gorilla glass can enhance durability while minimizing the risk of damage. Furthermore, exploring coatings that reduce glare can significantly improve visibility in environments with bright lighting, thus enhancing overall productivity.

Incorporating cover glass can also lead to improved energy efficiency in industrial PCs. The insulating properties of the glass can minimize temperature fluctuations, helping to maintain optimal operating conditions. As a result, less energy is required for cooling systems, which not only lowers operational costs but also contributes to a more sustainable industrial practice.

| Feature | Standard Industrial PC | Industrial PC with Cover Glass | Improvement (%) |

|---|---|---|---|

| Durability (Drop Resistance) | 1 meter | 1.5 meters | 50% |

| Scratch Resistance | H4 | H8 | 100% |

| Operating Temperature Range | -20°C to 60°C | -20°C to 70°C | 16.67% |

| Brightness | 250 cd/m² | 350 cd/m² | 40% |

| Glare Reduction | 15% | 5% | 66.67% |

Cover glass has emerged as a critical component in the design of industrial PCs, particularly due to its ability to enhance durability against environmental challenges. According to a report from TechNavio, the global industrial PC market is expected to grow at a CAGR of 9% from 2020 to 2025, driven by the increasing need for rugged solutions in various industries. Cover glass provides an additional layer of protection against harsh conditions, including dust, moisture, and extreme temperatures, which are common in industrial settings. This protective feature can extend the operational lifespan of industrial PCs, reducing downtime and maintenance costs significantly.

Additionally, studies indicate that cover glass can withstand impacts far better than standard materials, boasting a hardness rating of 9H on the Mohs scale. This resistance not only prevents physical damage but also ensures consistent performance over time. A report from MarketsandMarkets highlights that 30% of device failures in industrial environments are due to inappropriate handling and environmental conditions. By incorporating cover glass in industrial PC designs, manufacturers can effectively mitigate these risks and create systems that are not only durable but also reliable, capable of operating continuously in challenging settings.

The integration of cover glass into industrial PCs is increasingly recognized not only for its durability but also for its cost-effectiveness. According to a recent report by MarketsandMarkets, the global industrial PC market is projected to reach USD 4.88 billion by 2026, with a significant contribution from applications utilizing cover glass. This surge in demand is attributed to the enhanced protection cover glass provides against harsh environmental conditions, including dust, moisture, and mechanical impacts, which can considerably extend the lifespan of industrial devices.

Moreover, using cover glass can lead to substantial savings in maintenance and replacement costs. The International Data Corporation (IDC) noted that industries employing protective glass experience a 20% decrease in operational downtime due to equipment failures. This reduction is crucial in sectors such as manufacturing and logistics, where uptime is linked directly to productivity. Additionally, the initial investment in quality cover glass systems can yield a return on investment (ROI) of up to 150% over five years, making it a financially savvy choice for companies aiming to enhance their operations while managing their budgets effectively.

Cover glass solutions for industrial PCs have become increasingly popular, allowing for customization that aligns perfectly with specific operational needs. In an environment where durability and performance are paramount, these innovative designs not only safeguard sensitive components but also enhance the overall user experience. Whether it’s a robust anti-glare finish or enhanced touch sensitivity, customizing the cover glass can provide significant advantages tailored to unique industrial applications.

Tips: When choosing cover glass, consider the environmental factors that will impact its performance, such as dust, moisture, or temperature fluctuations. Opt for tempered glass for increased strength and durability. Additionally, ensure that your design accommodates for easy maintenance and replacement to minimize downtime.

Another key aspect of customizing cover glass is the potential for integrating unique functionalities. For example, incorporating anti-fingerprint technology not only helps maintain a clean surface but also promotes better visibility and usability in high-traffic areas. This level of customization can lead to improved efficiency and productivity within industrial operations.

Tips: Explore options for integrating additional features such as UV protection or antimicrobial coatings, which can enhance the longevity of the cover glass while addressing specific health and safety concerns. Be sure to consult with manufacturers to evaluate the best materials suited for your operational environment.