Advanced glass solutions for watch application

The watch crystal (or watch glass) serves as both a protective barrier and a visual gateway to the dial. Its material, durability, and clarity directly define a timepiece’s luxury positioning, functionality, and longevity. For watchmakers and glass processors, selecting the right substrate and finishing technique demands precision. This technical analysis explores the glass specifications dominating wristwatches and smartwatches today.

I. Core Watch Glass Materials: Performance & Application

- Organic Glass (Acrylic / “Hesalite”)

Composition: Polymethyl methacrylate (PMMA), a lightweight thermoplastic polymer.

Key Properties:

High impact resistance (virtually unbreakable)

Low scratch resistance (Mohs hardness: ~3)

Prone to yellowing under UV exposure

Applications: Vintage reissues, budget watches (<$100), children’s watches.

Processing: Easily molded into domed shapes; scratches buffed with polish.

Composition: Silica-based glass, chemically or thermally tempered.

Key Properties:

Moderate scratch resistance (Mohs hardness: 5–6.5)

Vulnerable to shattering upon impact

Resists keys/coins (hardness ≤5.5) but not sand (quartz hardness=7)

Applications: Mid-tier watches ($100–$500). Examples: Citizen’s “small blue hand” AO9000, fashion watches.

Processing: Tempering enhances surface compression; cutting/grinding pre-temper.

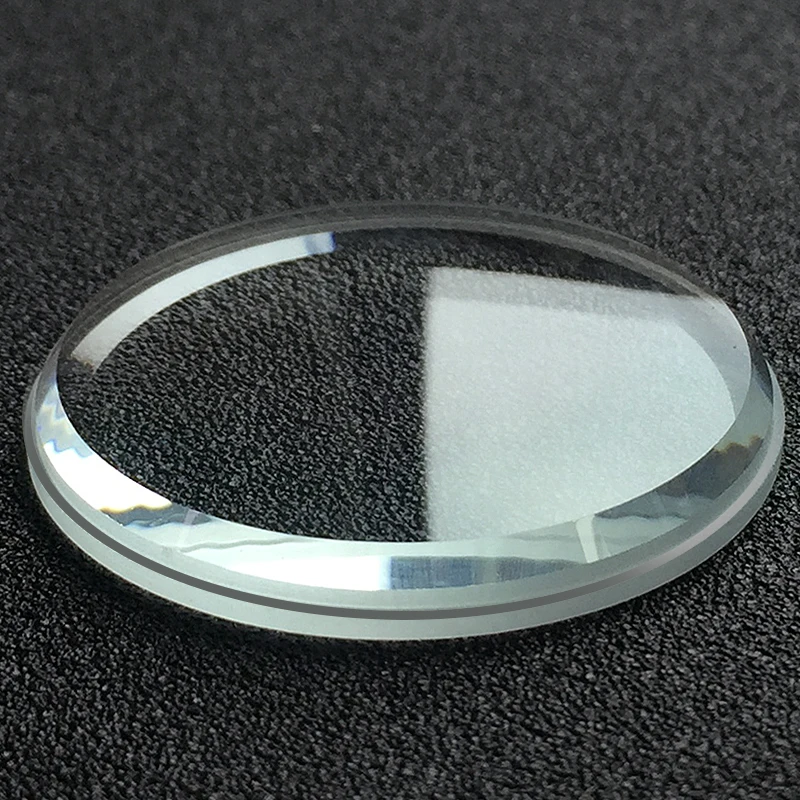

- Sapphire Crystal

Composition: Lab-grown aluminum oxide (Al₂O₃), identical to natural sapphire.

Key Properties:

Exceptional scratch resistance (Mohs hardness: 9)

Higher brittleness vs. acrylic/mineral glass

Transmits >90% visible light; chemically inert

Applications: Premium mechanical watches & smartwatches (>$500). Examples: Tissot Le Locle, Rolex Submariner, Huawei GT 2 Pro, TicWatch Pro 5 Enduro578.

Processing:

Cut from boules using diamond-coated tools

70–80% material waste during grinding/polishing

Complex shapes (e.g., box domes) multiply costs.

II. Critical Specifications & Dimension Standards

Diameter & Thickness

Men’s: 34–42mm (e.g., Daniel Wellington: 34/36/40mm; Longines Master: 40mm)

Women’s: 20–32mm (e.g., SK-II ultra-thin: 32mm)

Smartwatches: 39–46mm (e.g., Huawei GT 2 Pro: 46mm; TicWatch Pro 5: 45.4mm).

Thickness: 1.0–3.0mm (sapphire typically 1.5–2.5mm for durability).

III. Optical & Mechanical Parameters

Property Acrylic Tempered Glass Sapphire

Reflective Index 1.49 1.52 1.76–1.771

Density (g/cm³) 1.18 2.50 3.97

Thermal Shock Resistance High Medium Low

IV. Surface Finishing Technologies

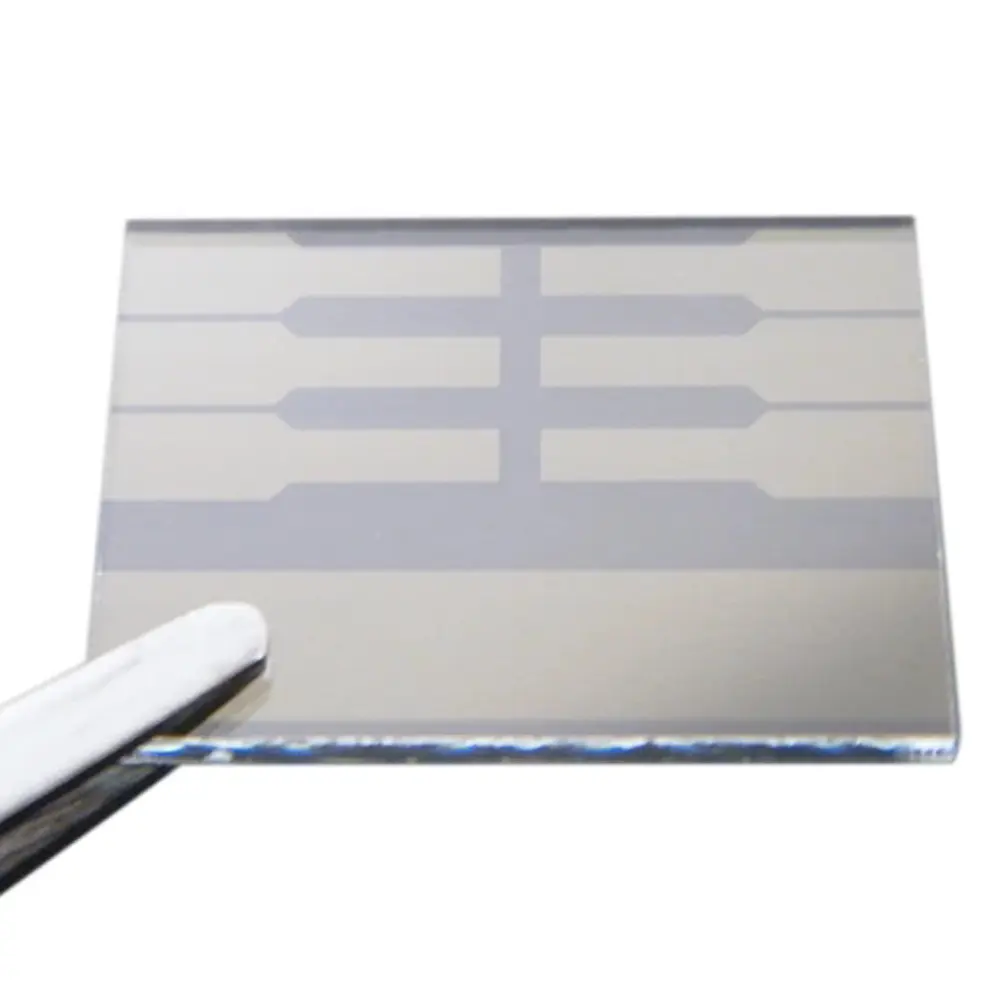

Anti-Reflective (AR) Coatings

Purpose: Reduce glare (critical for sapphire’s high reflectivity).

Edge Treatments

Polishing: Diamond abrasive wheels for sapphire/mineral glass.

Beveling: 45° angled edges (common on luxury dress watches).

Specialty Finishes

3D Shaping: Curved glass for smartwatches (e.g., OPPO Watch 2).

Textured Surfaces: Matte etching (sandblasting), laser-engraved patterns.

For more details learning, welcome to contact us: sales@saidavn.com

Phone

Phone Send Email

Send Email whatsapp

whatsapp Facebook

Facebook