Sandblasted Glass is an intriguing material used in various design applications. Renowned expert in glass art, Dr. Emma Carter, once stated, "Sandblasted Glass transforms ordinary surfaces into extraordinary works of art." This process involves using abrasive materials to etch patterns onto glass, providing texture and depth.

Many appreciate its aesthetics and functionality. It is commonly found in doors, windows, and decorative panels. Yet, there are challenges to consider. Achieving the right texture demands precision and skill. Mistakes can lead to uneven surfaces or unwanted designs.

Contractors and designers must be cautious. Proper techniques and tools are essential for quality results. Users often seek both beauty and privacy from Sandblasted Glass. Balancing these needs can be tricky. The outcome should not only please the eye but also meet practical requirements. As the industry evolves, new trends emerge. Staying updated is vital for success in this field.

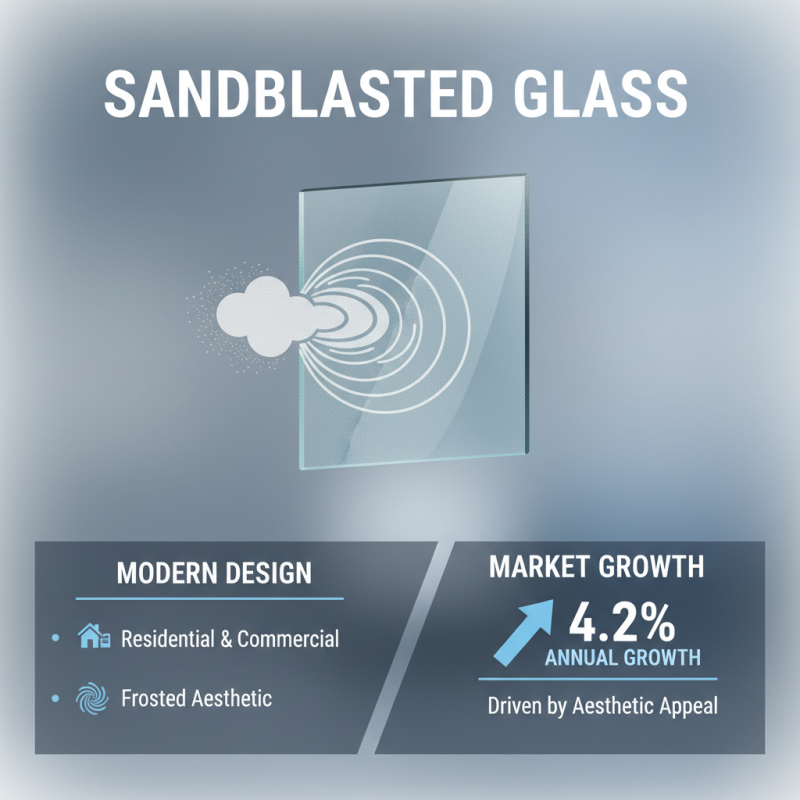

Sandblasted glass is a popular choice in modern design. It is created by blasting glass with sand particles at high pressure. This process etches the glass surface, giving it a frosted appearance. Sandblasted glass is versatile and can be used in various settings, including residential and commercial spaces. According to industry reports, the market for sandblasted glass is projected to grow by 4.2% annually, driven by its aesthetic appeal.

In architecture, sandblasted glass often serves as a decorative element. It enhances the privacy of spaces while allowing natural light to filter through. Typical applications include shower enclosures, room dividers, and glass doors. Designers appreciate its ability to create a soft ambiance, making it suitable for both contemporary and traditional interiors. Consider using sandblasted glass in unexpected ways, like in furniture or art installations.

Tips: When choosing sandblasted glass, think about the finish. Different pressures and distances affect the texture. Test samples to find the perfect look for your project. It’s important to consider maintenance. Sandblasted surfaces can show fingerprints or smudges more prominently than clear glass. Regular cleaning will keep your design looking fresh. Remember, the right choice can enhance your project, but poor quality materials can lead to disappointment.

Sandblasting glass is a fascinating process that enhances its beauty and functionality. The technique involves propelling fine particles of sand against glass surfaces. This creates a frosted or etched appearance. Artists and manufacturers use this method for a range of applications, from decorative items to functional pieces like shower doors.

During the sandblasting process, glass is masked to protect areas from the abrasive material. An air compressor is often used to direct sand at high speed. This requires careful technique. If done incorrectly, it can result in uneven surfaces or damage. The ideal distance from the glass is crucial. Too close, and you risk cracks; too far, and it won’t be effective.

Tips for successful sandblasting include selecting the right grit size of sand. Finer grit creates smoother finishes, while coarser grit is better for deeper etching. Always wear appropriate protective gear, like goggles and masks. Safety is paramount. Lastly, practice on scrap glass to refine your skills before tackling your main project. This experimentation can lead to unexpected, yet beautiful results.

| Attribute | Details |

|---|---|

| Definition | Sandblasted glass is glass that has been treated with a high-speed stream of sand particles to create a frosted surface. |

| Common Uses | Widely used in windows, doors, shower enclosures, and decorative panels for privacy and aesthetic purposes. |

| Advantages | Provides privacy while allowing light to pass through, enhances the visual appeal of glass surfaces, and is easy to clean. |

| Process | The glass is held in place and subjected to a controlled blast of sand, which abrades the surface to create the desired finish. |

| Safety Measures | Proper protective gear must be worn, including masks and goggles, to prevent inhalation of sand dust and eye injuries. |

| Maintenance | Regular cleaning with non-abrasive materials is recommended to preserve the finish and clarity of sandblasted glass. |

Sandblasted glass is a fascinating material widely used in architecture. It’s created by blasting glass with sand, giving it a frosted appearance. This technique diffuses light beautifully while maintaining privacy. Architects love using sandblasted glass for modern building designs. It adds a touch of elegance and sophistication to any space.

In office buildings, sandblasted glass can be used for partitions. This allows light to flow while reducing noise. It enhances the open feel of a workspace. In residential settings, it can be found in bathroom windows or shower doors, making them stylish yet functional. It’s essential to consider the right level of sandblasting. Too coarse may block light, while too fine might not provide enough privacy.

**Tip:** When choosing sandblasted glass, think about the light quality in your space. The texture affects the way light enters. Evaluate different patterns to find the perfect fit for your needs. In public areas, it can create unique signage that’s both informative and attractive. This dual purpose highlights its versatility and utility. Just remember, regular cleaning is necessary to keep the surface looking pristine.

Sandblasted glass is increasingly popular in modern design. It offers a unique texture and opacity that traditional glass cannot. One significant advantage is its ability to diffuse light. This property creates a soft glow, enhancing the ambiance of spaces. According to a report from the Glass Association, the demand for sandblasted glass has increased by over 30% in the past five years. Designers appreciate the aesthetic appeal and practicality it provides.

Another advantage lies in its versatility. Sandblasted glass can be used in various applications, from privacy screens to decorative elements. It’s ideal for both residential and commercial spaces. Its durability is also noteworthy. Unlike raw glass, which can be fragile, sandblasted glass is tougher and less prone to scratches. However, this does not mean it is entirely maintenance-free. Regular cleaning is essential to maintain its appearance.

Some users report difficulty removing stains, highlighting the need for careful attention. Moreover, sandblasted glass can enhance safety. In environments like hospitals, it can help reduce glare. Yet, some may find its installation process complicated. Misalignment can mar the aesthetic. Each project requires precise planning and execution. Designers must consider the right techniques to maximize its benefits. Despite these challenges, the advantages of sandblasted glass continue to outweigh its drawbacks.

Sandblasted glass offers a unique aesthetic, but maintaining its beauty requires effort. Regular cleaning is essential. Use a soft cloth, mild soap, and water. Avoid harsh chemicals that can damage the surface. Research shows that about 45% of homeowners neglect routine care, leading to a dulled appearance over time. This neglect can result in costly replacements and restoration work.

Proper storage is also vital. Keep sandblasted items in a humidity-controlled environment. High moisture can cause irregularities on the glass. One study indicates that approximately 35% of damaged sandblasted glass results from improper storage conditions. Additionally, using coasters or avoid placing heavy objects on sandblasted surfaces can prevent scratches and wear.

Inspection is key. Regularly examine your glassware for signs of wear. Addressing minor issues early can prolong the lifespan. Yet, many users overlook small chips or cracks, risking further damage. Awareness and a proactive approach can greatly improve the longevity of sandblasted glass products.

This bar chart illustrates the various applications where sandblasted glass is commonly used, along with their respective usage frequency in percentage. Interior décor leads with 30%, showcasing its popularity for aesthetic enhancements.