CUSTOMIZATION FOR ALL GLASS FABRICATION

Material & thickness:

● Saida offers various types of glass that can be used according to the customer's needs and requirements: Soda-line , Borosilicate, Aluminosilicate, Ceramics, Quartz, Sapphire, Optical Glass and so on.

Size & Shape

● Automatic cutting to specific size, CNC grinding/profiling, drilling to meet various shape demands.

Cutting

laser cutting & CNC milling

& waterjet cutting

CNC Profiling

edge grinding & cNC profiling

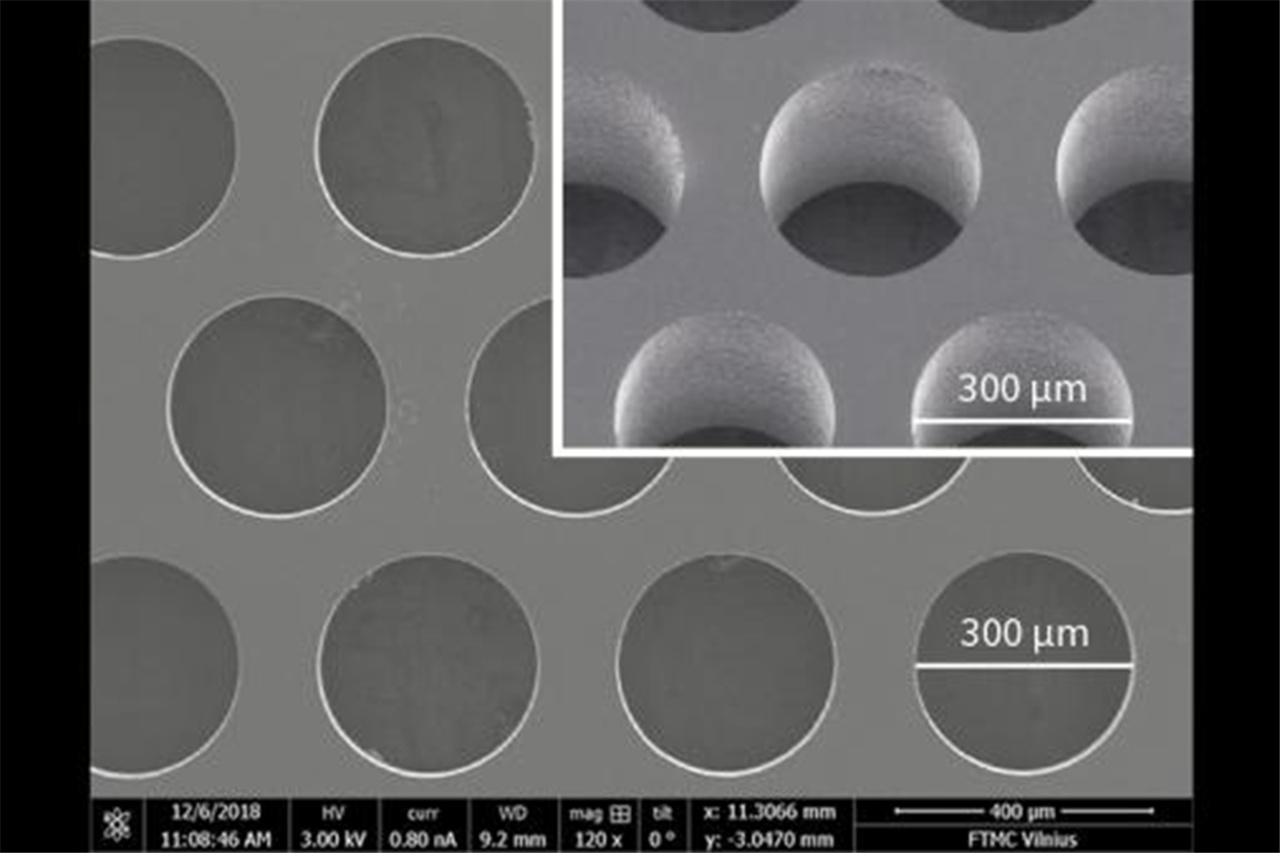

Drilling

CNC & laser drilling

Chemical and thermal curing

● Depended on impact resistance, application and material thickness desired, Saida Glass can provide the following method to increase the resistance of glass.

Thermal tempering

Chemical strengthening

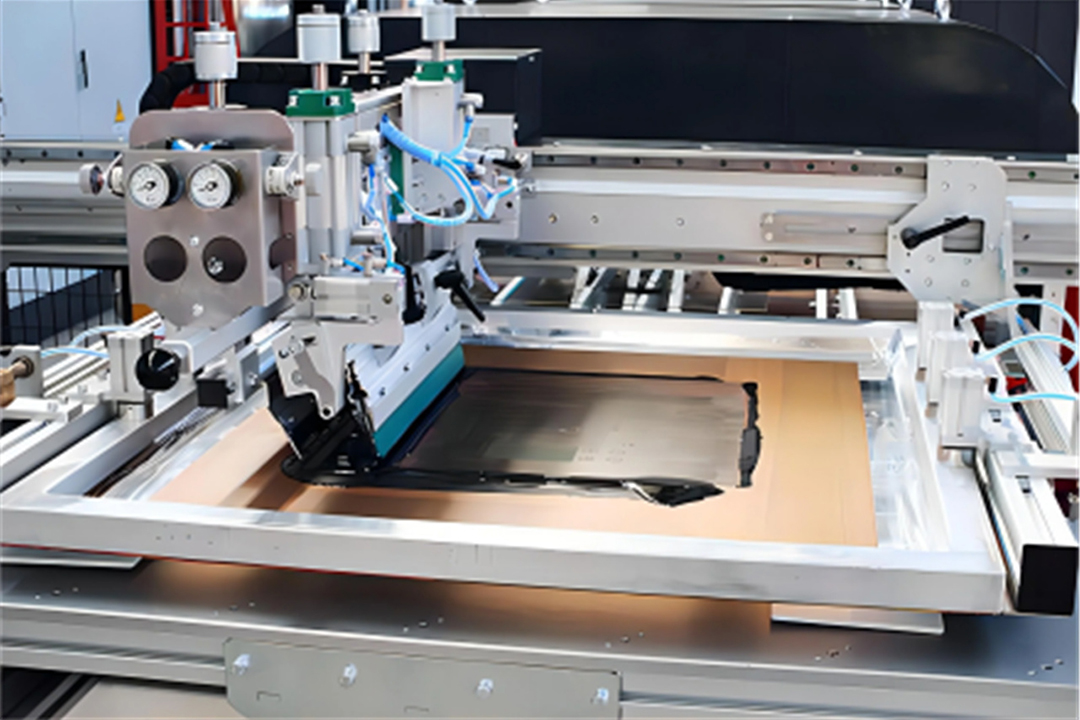

Customization Printing

● Customization printing service also is available in Saida. There are almost no limits to the design possibilities: specialized organic, digital and ceramic printing and glass can be printed translucent or opaque upon request, including logos or symbols, for example.

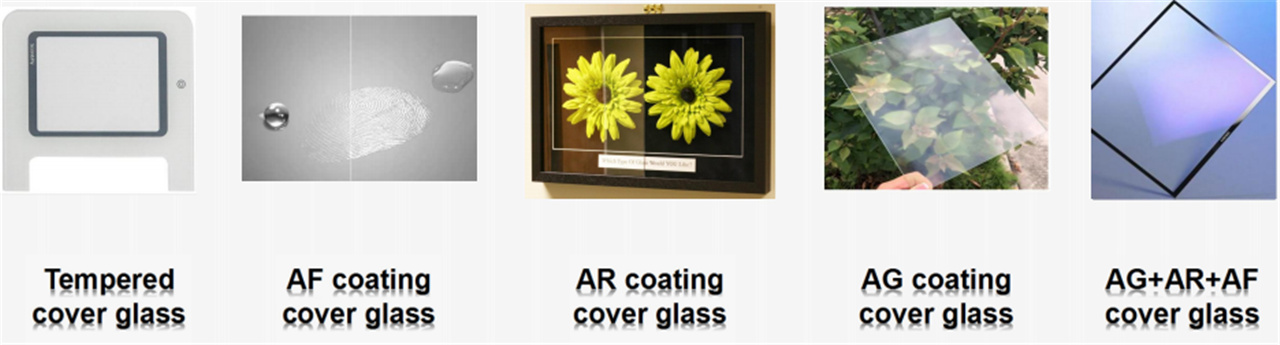

Often different application purpose requires different surface treatment:

● Anti-reflective in single or double side

● Anti-glare in single or double side

● Anti-fingerprint

● ITO/FTO conductive capacity

● Mirror

Cleaning

● Saida has multiple effective wash stations (Ultrasonic and flat plate cleaning)to remove dust, finger-prints, and other contamination during processing.

Phone

Phone Send Email

Send Email whatsapp

whatsapp Facebook

Facebook