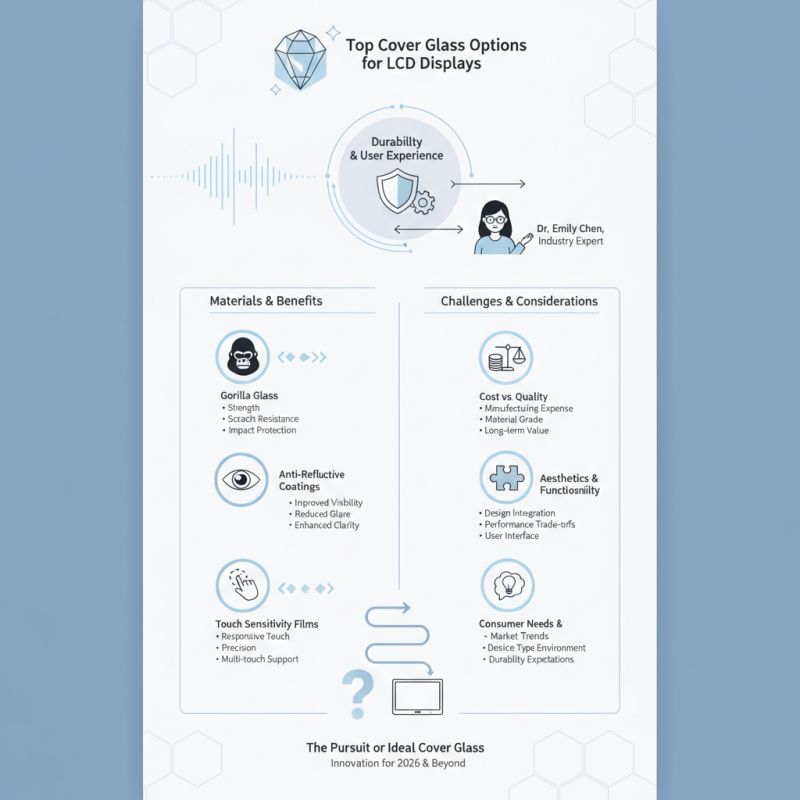

In the evolving landscape of LCD displays, the choice of cover glass has become crucial. Industry expert Dr. Emily Chen states, "The right cover glass can enhance durability and user experience." As companies prepare for 2026, understanding the top cover glass options is essential for product innovation.

Cover glass for LCD display serves multiple purposes. It provides protection, improves clarity, and can enhance touch sensitivity. Each material has its unique benefits and drawbacks. For instance, Gorilla Glass is known for its strength, while anti-reflective coatings improve visibility.

As we explore the market, challenges remain. Manufacturers must balance costs with quality. Selecting the perfect cover glass is not straightforward. The decision impacts both aesthetics and functionality. Businesses need to reflect on their choices and how they align with consumer needs. The pursuit of the ideal cover glass for LCD displays continues to be a complex journey.

In 2026, the choice of cover glass for LCD displays revolves around a few key materials. Glass types like chemically strengthened and laminated glass are gaining traction. Each offers distinct advantages. Chemically strengthened glass excels in durability but may impact clarity. Laminated glass, on the other hand, enhances image quality while adding weight.

When selecting cover glass, consider the environment. A thicker glass may resist scratches better but can result in a heavier display. Weight is crucial for portable devices. A balance must be struck between protection and usability. Some manufacturers may overlook this. They need to evaluate clear advantages versus added bulk.

Tip: Always test different materials. What works in theory may not perform in practice. Seek feedback from actual users. Their insights are invaluable. Remember, the right cover glass can elevate the user experience tremendously, but the wrong choice may lead to regrets. Keep exploring new options as technology evolves. Adjust your choices based on real-world applications instead of just specs.

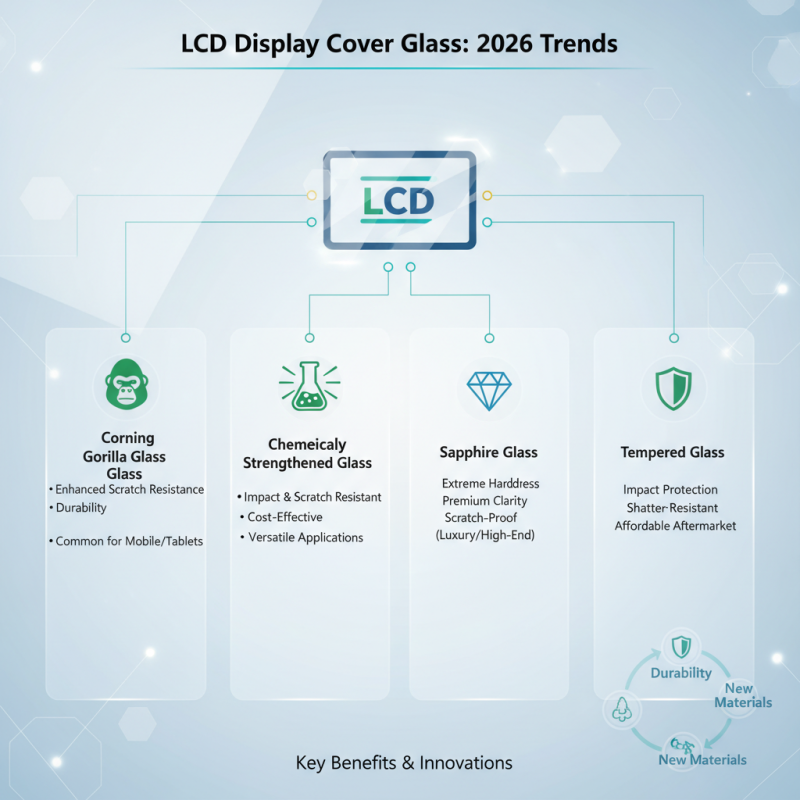

When considering cover glass options for LCD displays in 2026, it's vital to focus on their key properties. Durability is paramount; users expect their displays to resist scratches and impacts. The choice of material can influence this significantly. For example, Gorilla Glass is popular, but alternatives like sapphire offer unique advantages. Each material has pros and cons.

Transparency is another crucial property. High light transmission enhances the display's brightness and clarity. However, finding a balance between durability and transparency can be challenging. Some coatings may improve scratch resistance but reduce light quality.

Furthermore, thermal stability plays a role in performance. Cover glass must withstand temperature variations without warping. In environments with extreme heat or cold, this stability is tested. While manufacturers strive for perfection, inconsistencies in production can lead to unexpected failures. The quest for the ideal cover glass is ongoing, leaving room for exploration and innovation.

The market for LCD displays is evolving rapidly. By 2026, various trends will influence the selection of cover glass options. Recent data from industry reports indicates that the demand for high-performance cover glass will rise significantly. This shift is driven by advancements in display technologies and consumer preferences.

One key trend is the increasing need for lightweight and durable materials. Manufacturers are focusing on materials that offer better scratch resistance and lower weight. This pursuit often leads to more complex production processes. For instance, tempered glass is gaining popularity but can be more expensive. Striking a balance between cost and performance remains crucial.

Tip: When choosing cover glass, consider scratch resistance and weight. These factors can affect user experience significantly. Another trend is sustainability. Eco-friendly materials are becoming essential, as consumers prioritize environmental impact. This may result in higher initial costs but can enhance brand reputation.

Moreover, the integration of touch technology requires glass that can withstand constant interaction. Touchscreen displays need to be responsive while maintaining clarity. Some manufacturers are experimenting with new coatings to improve touch sensitivity without compromising durability. Still, finding the right coating can be challenging.

Tip: Evaluate the total cost of ownership, not just the initial price. Cheaper options may incur higher replacement costs over time. As the industry progresses, adapting to these trends will be necessary for success in the LCD display market.

In 2026, the cover glass options for LCD displays are vast, shaped by evolving technology and market needs. The increasing demand for durability and clarity has driven innovations in glass materials. Corning's Gorilla Glass and chemically strengthened glass remain popular for their scratch resistance. However, emerging alternatives, such as sapphire and tempered glass, are gaining traction, offering unique benefits and challenges.

A comparative analysis reveals that Gorilla Glass excels in drop resistance, while tempered glass often provides better optics. Sapphire, though scratch-resistant, has higher costs and weight considerations. Industry reports suggest that over 30% of manufacturers prioritize optical clarity over durability in their choices. It raises questions about balancing performance with cost-effectiveness.

Tips: When selecting cover glass, consider the environment where the LCD will be used. Will it face harsh conditions? Assess the trade-offs carefully. Also, keep an eye on market trends. Innovations can disrupt established preferences quickly. Regularly reevaluate your choices based on performance data and user feedback. This reflection can lead to better-suited solutions for specific applications. Choices today can impact long-term satisfaction.

The evolution of cover glass for LCD displays is crucial for smartphone and tablet manufacturers. In 2026, we expect to see significant innovations that enhance durability. Advanced materials will likely dominate the market. These materials may include new composites and coatings that resist scratches and impacts.

One exciting possibility is self-healing technology. Imagine a display that can repair minor scratches automatically. Such a feature would be a game-changer for everyday users. Additionally, anti-reflective and anti-fingerprint coatings will improve the user experience. These coatings could make screens easier to read in sunlight, reducing glare significantly.

However, there are challenges to overcome. Manufacturing processes must keep up with new materials. Quality control remains a concern; defects can undermine durability promises. Furthermore, the balance between weight and strength is delicate. As designs evolve, finding the right materials to meet consumer demands is essential. The industry must continue to innovate while addressing these ongoing issues.

| Material Type | Thickness (mm) | Hardness (Mohs) | Scratch Resistance | Cost (USD/m²) |

|---|---|---|---|---|

| Tempered Glass | 2.5 | 6-7 | High | $20 |

| Gorilla Glass | 1.8 | 7 | Very High | $30 |

| Sapphire Glass | 2.0 | 9 | Extreme | $50 |

| Plastic Coating | 1.0 | 5 | Moderate | $10 |

| Polycarbonate | 1.5 | 4-5 | Good | $12 |