Optimizing glass deep processing techniques can significantly enhance product quality. Many manufacturers face challenges in achieving ideal results. Factors like equipment choice, raw material selection, and processing parameters play a crucial role.

The glass deep processing industry demands precision. Techniques such as bending, laminating, and coating must be fine-tuned for optimal performance. It’s essential to assess each step closely. Small adjustments can lead to notable improvements in durability and clarity.

However, not all approaches yield perfect outcomes. There is room for error, and ongoing evaluation is necessary. Manufacturers often overlook minor details. Focusing on these aspects could unlock better efficiency and productivity in the long run. Embracing a mindset of continuous improvement is vital for success in glass deep processing.

Glass deep processing techniques are crucial in various industries. They enhance the strength and durability of glass products. This process involves cutting, polishing, and tempering glass. Each step requires precision and care, making it essential for achieving high-quality results.

Understanding these techniques can significantly impact the final product. For example, improper polishing can leave scratches. Poorly tempered glass may shatter under stress. Thus, attention to detail is vital. Workers must be trained to recognize defects early in the process.

Additionally, optimization is an ongoing challenge. The balance between efficiency and quality is delicate. Speeding up production can sometimes lead to mistakes. Regular training and process reviews can address these issues. It’s important to foster a culture of continuous improvement to enhance glass processing outcomes.

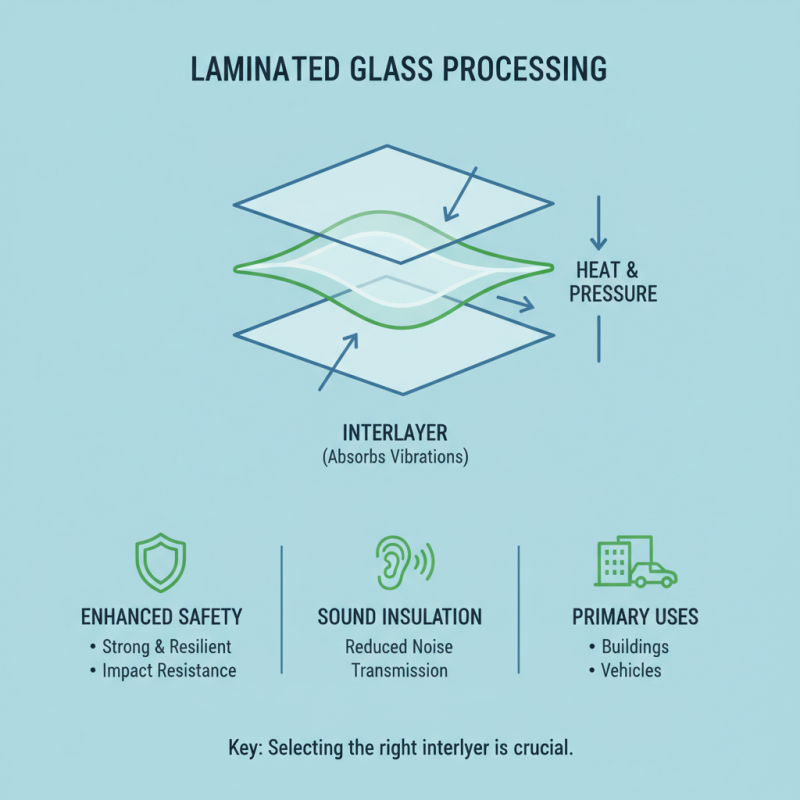

When it comes to glass deep processing, various techniques offer distinct benefits. Laminated glass is one of the key methods, enhancing safety and sound insulation. This process involves layering glass with interlayers that absorb vibrations. The result is strong and resilient glass, perfect for buildings and vehicles. It’s crucial to select the right interlayer to meet specific needs.

Another popular technique is tempered glass. This treated glass undergoes a heating and cooling process, making it four to five times stronger than ordinary glass. It is widely used in shower doors, glass railings, and facades. However, it's essential to consider the limitations. Once tempered, this glass cannot be cut or altered.

Coating is another significant method. By applying specialized coatings, glass can gain functionalities such as UV protection and energy efficiency. These coatings can enhance durability and aesthetic appeal. Yet, achieving the right adhesion is a challenge. An improper application can lead to peeling or fading over time. These techniques, while effective, require careful consideration to ensure optimal performance and longevity.

In the glass processing industry, measuring efficiency is crucial. Metrics such as yield rate, processing speed, and energy consumption provide deep insights. According to a recent industry report, optimizing yield rates can boost profit margins by up to 25%. These metrics allow manufacturers to pinpoint inefficiencies in their processes.

Processing speed is another vital measure. It impacts overall productivity directly. An analysis revealed that companies with streamlined processing methods increased output by 30%. However, not all techniques yield such results. Challenges remain in balancing speed and quality. Too much focus on speed may compromise the final product.

Energy consumption is often overlooked but significant. A well-known study indicated that optimizing energy usage can reduce costs by 15%. Yet, many facilities report no clear strategy for energy efficiency. They might need to revisit their approaches and identify new technologies to achieve sustainable processing methods. This reflection can help in achieving better overall performance in glass processing.

Advancements in glass processing technologies have transformed the industry. Robotics and automation streamline production. However, not all implementations yield expected results. Proper training for operators is crucial. Without skilled personnel, even the best technology can falter.

Incorporating smart sensors into processes allows for real-time monitoring. This helps in adjusting parameters on the go. Yet, it requires upfront investment and time for integration. Some facilities struggle with these transitions. The operational downtime can be a significant setback for businesses. Therefore, a phased approach may be more effective.

Data analytics can enhance decision-making. By analyzing production data, companies can identify flaws. This can lead to improvements in quality control. However, not all data is actionable at first glance. Teams need to reflect on how to interpret this information. Continuous learning is necessary for optimizing glass deep processing techniques.

Optimizing glass deep processing techniques presents notable cost-benefit advantages. According to a recent industry report, companies can reduce production costs by as much as 15% through energy-efficient machinery. This not only lowers overhead but also enhances productivity. Moreover, upgrading equipment can sometimes lead to a 25% increase in output quality, which is pivotal in competitive markets.

However, the initial investment in new technology can be daunting. Organizations must weigh potential savings against upfront costs. If a company spends heavily on high-tech machinery, the ROI may take time to materialize. One study indicates that nearly 40% of businesses see a payback period of three to five years. This delay can pose challenges, particularly for smaller firms lacking vast financial resources.

Additionally, some techniques may show diminishing returns. For instance, while advanced cutting tools can improve efficiency, they may require frequent recalibration. This can lead to increased downtime, which offsets productivity gains. Reflecting on these factors is crucial for any business considering an overhaul of their glass processing techniques. Making informed decisions based on empirical data is essential for sustainable growth.

| Optimization Technique | Initial Cost ($) | Annual Savings ($) | Payback Period (Years) | Performance Increase (%) |

|---|---|---|---|---|

| Automated Cutting Technology | 50,000 | 15,000 | 3.33 | 20 |

| Advanced Tempering Process | 75,000 | 25,000 | 3.00 | 25 |

| Precision Coating Application | 30,000 | 10,000 | 3.00 | 15 |

| Digital Print Technology | 40,000 | 12,000 | 3.33 | 18 |